In recent decades, technological advancements in the construction industry have significantly transformed the design and execution of steel frame structures. One of the most prominent trends is the integration of prefabrication and modular construction methods, delivering unique technical, economic, and environmental benefits.

Definition: Prefabricated and Modular Systems

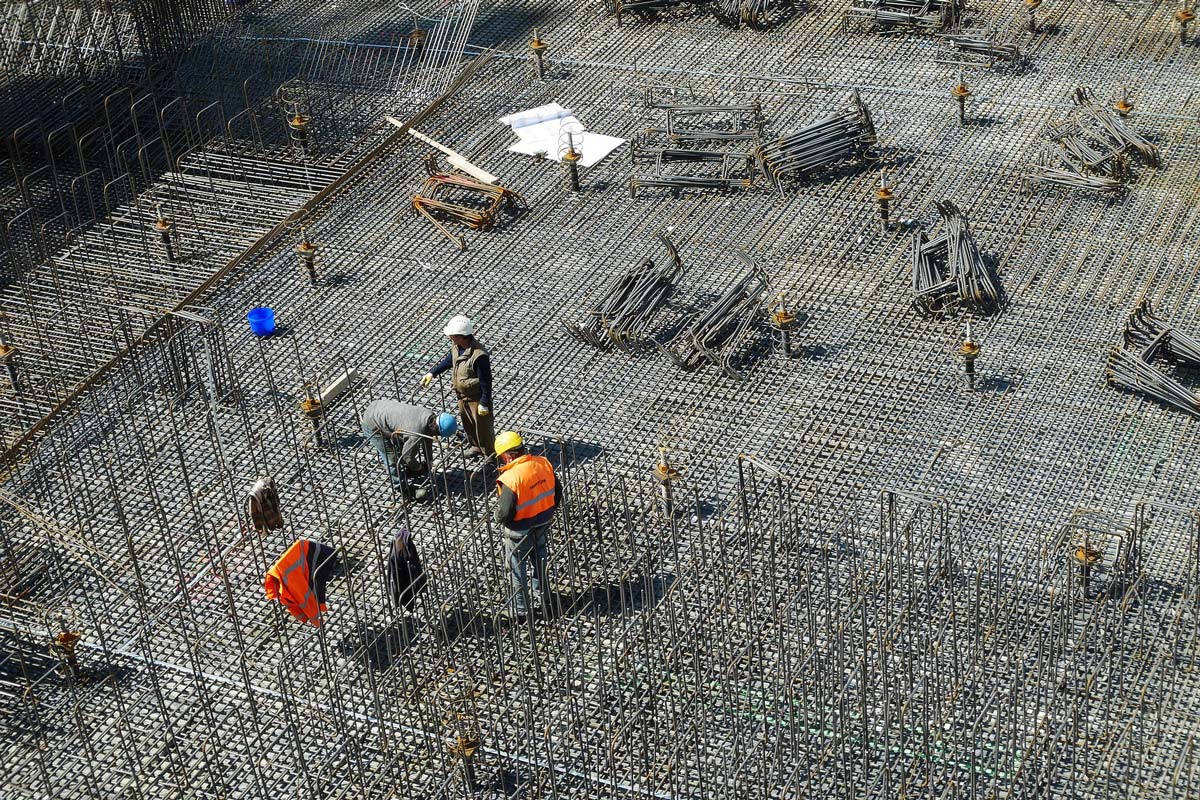

Prefabrication refers to manufacturing structural components in a controlled factory environment before transporting them to the construction site for final assembly. Steel members—columns, beams, braces, and connectors—are fabricated with high precision using advanced machinery such as laser cutting systems, CNC machines, robotic welding, and automated drilling.

Modular construction goes a step further, producing fully assembled units—including structural elements, finishes, installations, and even façades—in factory conditions. These modules, such as rooms, corridors, bathrooms, or other detachable building sections, are directly installed or connected on‑site.

Advantages of Prefabricated and Modular Technology in Steel Framing

- Reduced Construction Time Parallel workflows—fabrication in the factory and site preparation—significantly accelerate project delivery.

- Enhanced Build Quality Controlled factory conditions and rigorous process monitoring ensure superior quality and uniformity compared to on‑site welding and assembly.

- Improved Safety Minimizing high‑risk activities such as outdoor welding and cutting improves worker safety and reduces hazards associated with working at heights or in adverse weather.

- Reduced Waste & Optimized Resource Use Precise engineering and fabrication result in minimal material waste, optimizing resource consumption.

- Environmental Benefits Reduced heavy equipment movement, fewer truck deliveries, lower noise levels, and minimal site pollution contribute to a smaller environmental footprint.

Key Technologies Used

- CNC & Laser Cutting: Enables highly precise measuring, cutting, and drilling for flawless assembly.

- Robotics & Artificial Intelligence: Robotic welding and automated assembly reduce human error and increase production speed.

- Building Information Modeling (BIM): Software tools like TEKLA Structures allow 3D design, clash detection before construction, and improved project management.

- Bolted Connections: Promote ease of transport, higher dismantling capability, and future recyclability compared to on‑site welding.

- Modular Transport Solutions: Specialized heavy lifting and module‑handling methods streamline installation processes.

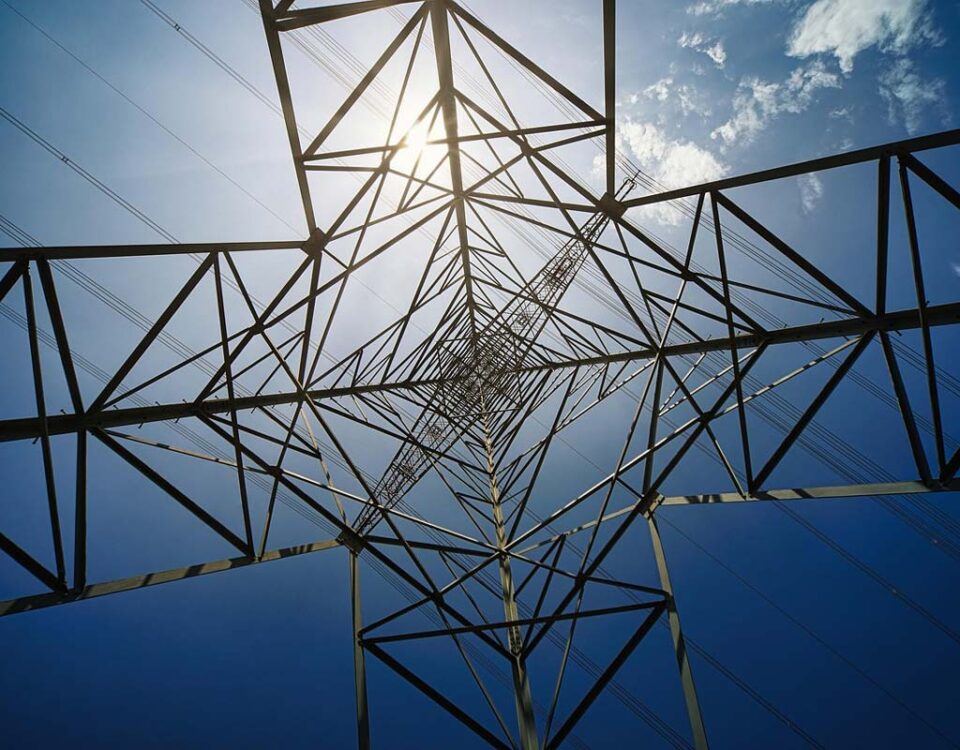

Applications & Potential

These technologies are particularly effective in industrial halls, high‑rise towers, steel bridges, hotels, large‑scale residential complexes, and temporary structures. They reduce overall project costs, increase efficiency, enhance sustainability standards, and open new possibilities for complex, customized architectural solutions.

Challenges & Future Outlook

While full implementation requires initial investment, technical skill upgrades, and adaptation to modern standards, ongoing trends in industrialized and quality‑driven construction indicate that prefabrication and modular methods are becoming increasingly dominant in steel structures.

The future of construction is industrialized, intelligent, and environmentally conscious—with prefabricated and modular steel frames playing a pivotal role in this transformation.