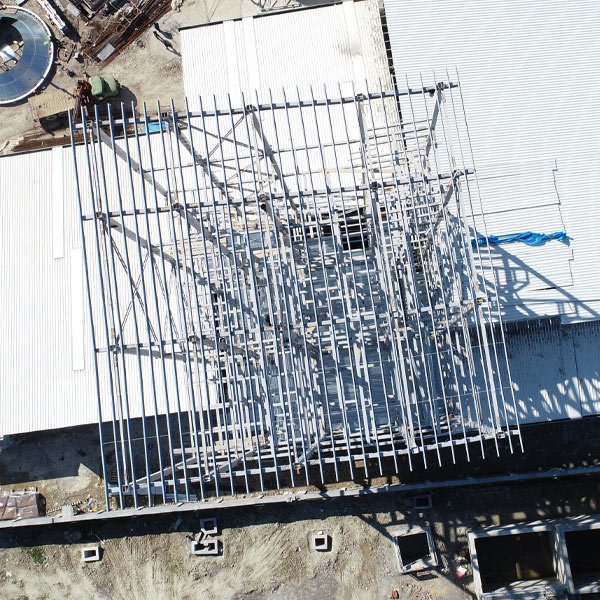

Asalem Bridge – Steel Arch Bridge Project

In this project, to achieve the specified negative camber in the longitudinal and transverse girders, all web plates for these members were cut using CNC plate cutting technology.

The Asalem Bridge is a steel arch bridge with a main span of 70 meters, width of 28 meters, and a total structural weight of 1,000 tons. It was awarded to Lahij Souleh by the Ministry of Roads & Urban Development in 2020 (1399).

The bridge features two side pylons and one central pylon:

Side Pylons: Height 18 m from the deck surface, comprised of 5 segments with a total weight of 80 tons.

Central Pylon: Height 15 m from the deck surface, comprised of 5 segments with a total weight of 120 tons.

Deck Structure:

Two outer longitudinal girders: 4 segments, total weight 60 tons, prismatic box section with a negative camber of 10 cm at midspan.

One central longitudinal girder: 4 segments, total weight 100 tons, H‑box prismatic section (three webs) with a negative camber of 15 cm at midspan.

Pylon Section Details:

Side pylons: Non‑prismatic box sections, transitioning from BOX‑1000×400×35 at base/top ends to BOX‑400×1000×35 at the crown.

Central pylon: Non‑prismatic box sections, transitioning from BOX‑1000×1000×60 at base/top ends to BOX‑500×500×50 at the crown.

According to the structural design, the crown axis of each side pylon is offset by 1,994 mm relative to the axis of its corresponding outer longitudinal girder, and the crown axis of the central pylon is offset by 2,261 mm relative to its corresponding central girder. This significant eccentricity made pipe assembly for all pylons highly complex.

The two pylons are connected using 14‑inch diameter tubular braces arranged in a honeycomb pattern. Each “tree” branch pipe installed on the pylons had its own unique rotation and angle, defined by 3D coordinates in the TEKLA Structures model, ensuring accurate assembly.

All pipe cuts were performed using CNC tube cutting for precise angle preparation. Likewise, due to the curved and variable cross‑sections of the pylons, all plates were CNC‑cut to ensure absolute accuracy with zero tolerance for error.