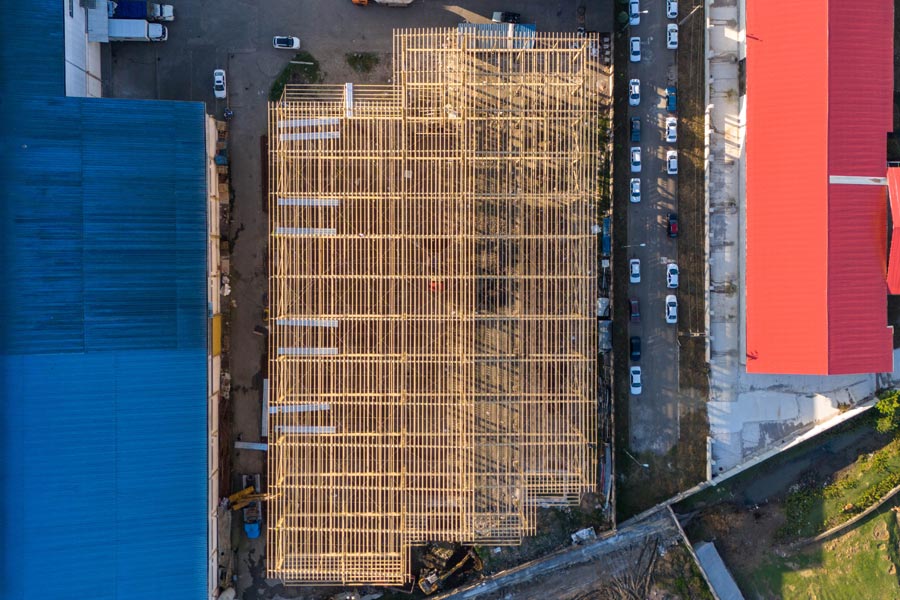

Phase Three of Cooperation between Lahij Souleh and Naderi Company

Phase Three of cooperation between Lahij Souleh Company and Naderi Company stands as one of the most notable examples of combining high production capacity, advanced equipment, and intelligent project management in the country’s steel structure industry.

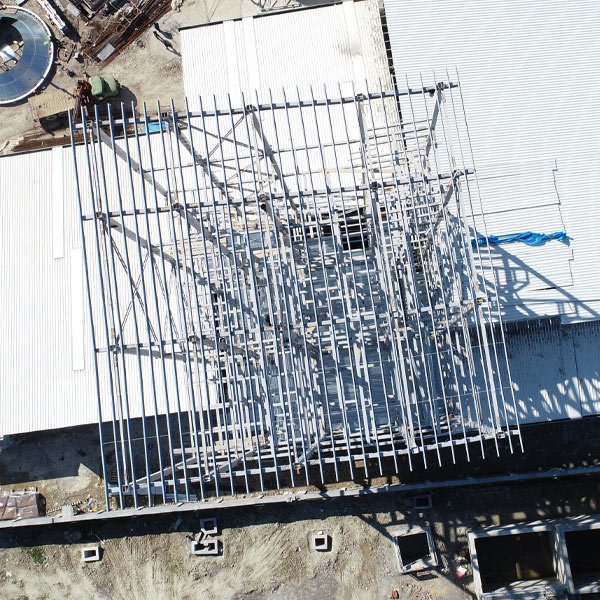

In this project, a massive steel structure weighing 450 tons was designed and fabricated. The manufacturing process was completed within an intense 60‑working‑day schedule, adhering fully to all engineering, safety, and quality standards. The defining feature of this phase was Lahij Souleh’s execution strategy in addressing the client’s time constraint—only a short period was allotted for completing the entire operation.

Under such conditions, the technical and execution teams of Lahij Souleh, drawing upon their extensive experience, launched the installation process in parallel with fabrication starting on the 30th day of production. This extraordinary measure required perfect coordination between the manufacturing, transportation, and installation units to prevent any downtime. Installation was carried out simultaneously using three powerful cranes of 50‑ton, 20‑ton, and 10‑ton capacities, all part of Lahij Souleh’s fully equipped fleet.

Planning the transport routes for structural components, precision positioning of cranes at the project site, coordination of teams working at height, and moment‑by‑moment operational management were among the factors that ensured the highest level of execution quality alongside unprecedented speed. Every component was ultimately installed with millimeter‑level precision, and the project was delivered ahead of schedule—resulting in complete client satisfaction and reinforcing Lahij Souleh’s reputation as a reliable partner for large‑scale projects.

This accomplishment not only reflects Lahij Souleh’s operational capacity and flexibility but also proves that the combination of speed, quality, and proper management can be realized to perfection in heavy industrial and construction projects.

Ultimately, Phase Three of cooperation with Naderi Company was recorded in Lahij Souleh’s portfolio of achievements as a successful example of simultaneous fabrication and installation under strict time constraints.