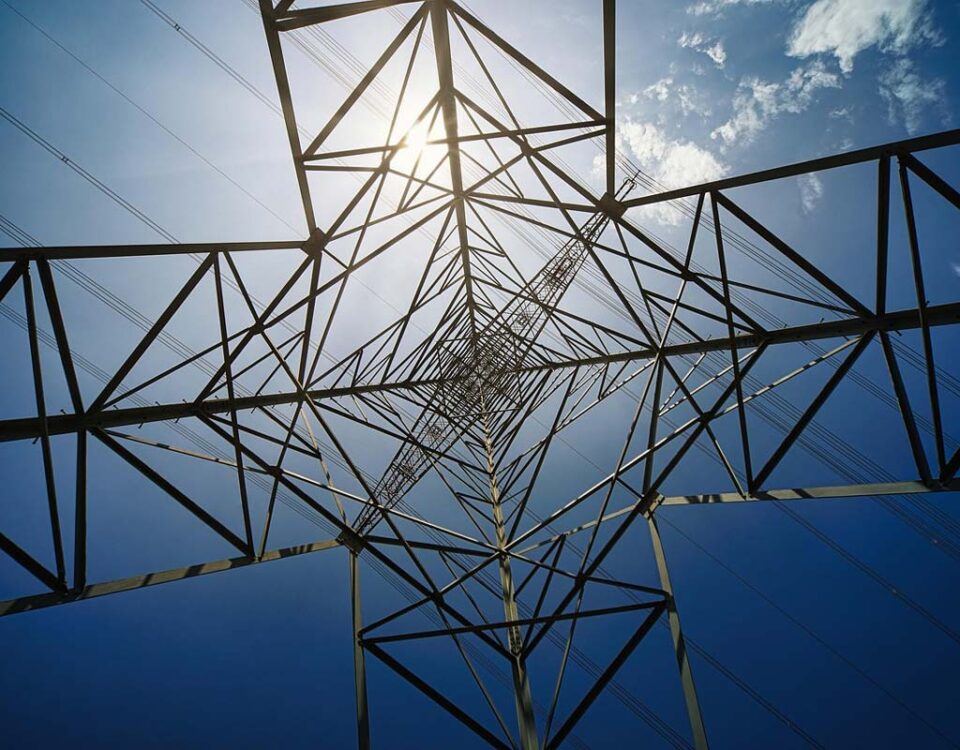

Steel frame structures are widely favored in civil engineering projects due to their high load‑bearing capacity, ductility, and fast execution. However, their long‑term durability depends heavily on proper maintenance and protection. Factors such as corrosion, rust, mechanical damage, and prolonged sunlight exposure can significantly impact structural integrity. Neglecting maintenance routines may shorten a structure’s service life, reducing strength and safety.

Corrosion: The Primary Threat

The most critical enemy of steel structures is corrosion caused by moisture, water, and environmental chemicals. In high‑humidity regions or coastal areas, corrosion progresses much faster. Rust‑induced reduction in sectional thickness can severely compromise structural capacity.

One of the most common protection methods is the application of specialized anti‑rust paints and epoxy coatings, preventing water and oxygen penetration. Coatings should be periodically inspected and reapplied when cracks or peeling are detected, as such defects become starting points for corrosion.

Galvanization

Applying a zinc coating (galvanizing) to steel members, particularly those directly exposed to moisture, is highly effective in prolonging lifespan. Galvanization acts both as a physical barrier and a sacrificial layer, offering protection for several decades.

Cleaning and Environmental Control

Regular removal of dust, mud, chemical contaminants, and bird droppings is vital. Such deposits can trap moisture or trigger chemical reactions leading to accelerated corrosion. In industrial or urban settings, scheduled wash‑downs are recommended.

Periodic Technical Inspections

Routine inspections, at least annually, are a cornerstone of any maintenance program. These inspections should assess:

- Presence of cracks, dents, or fatigue signs

- Reduction in member thickness

- Condition of protective paints and coatings

- Loose bolts/nuts

- Deficiencies in welds

Upon detecting any sign of corrosion, deformation, or cracking, immediate technical evaluation and corrective action must be undertaken to prevent further deterioration.

Connection Protection

Connections—bolts, nuts, welds—are among the most vulnerable points in steel frames. Application of anti‑corrosion paints, protective greases, or specialized sealants is essential. In cases of severe exposure, advanced protective systems should be applied to these areas.

Protection in Aggressive Environments

In facilities with potential contact with corrosive chemicals, acid‑resistant and oil‑resistant coatings should be employed. Proper rainwater management and site drainage further help keep moisture away from structural members.

Fire Resistance Measures

Thermal insulation and fire‑resistant coatings greatly enhance safety against fire hazards. Extreme heat can weaken steel significantly; therefore, fireproofing critical members—especially in tall buildings—per code requirements is recommended.

Maintenance Program and Record‑Keeping

A structured maintenance plan, coupled with detailed records of inspections and repairs, is an essential part of asset management for steel frame structures. Proactive care can extend service life, reduce major repair costs, and minimize safety risks.