Advanced Facilities and Equipment

“From the heart of industry, building tomorrow , Lahij Souleh the leading pioneer in steel and metal structures.”

Advanced Facilities and Equipment

از دل صنعت، برای ساخت فـردا

Plasma Cutting

Plasma Cutting

Advanced equipment for precise, high‑speed cutting of metals, using laser or plasma technology to deliver clean, burr‑free cutting lines.

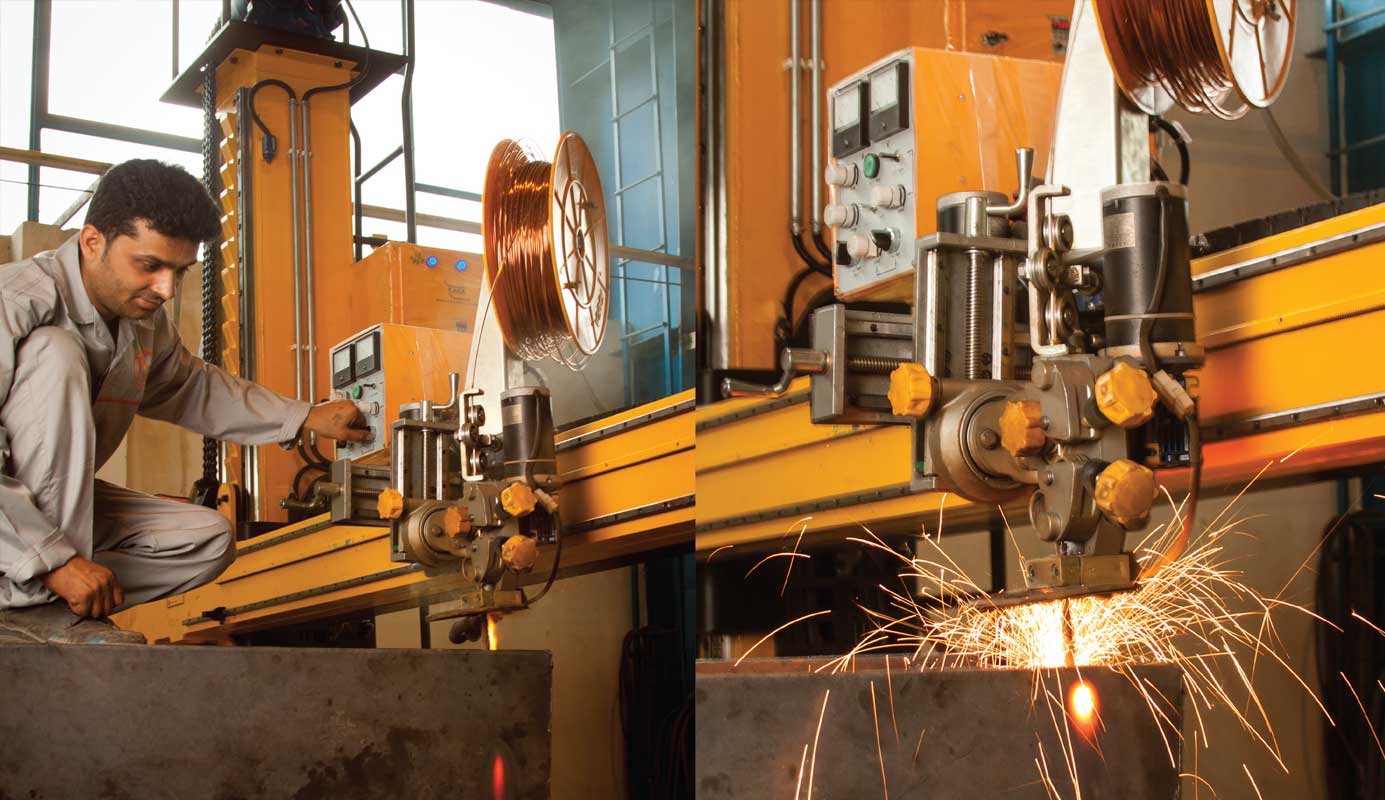

Submerged Arc Welding (SAW)

Submerged Arc Welding (SAW)

A specialized welding method in which the electric arc is struck beneath a layer of granular flux, enhancing quality and providing greater control during the joining process.

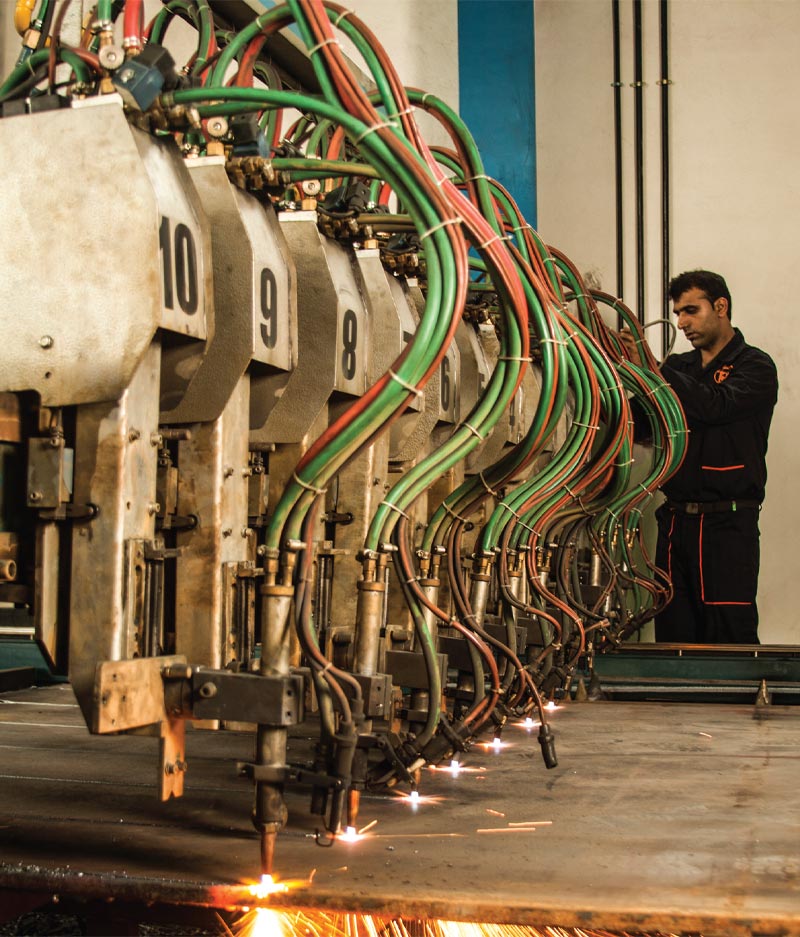

CNC Hot Cutting

CNC Hot Cutting

This machine can cut steel plates with high precision into complex shapes, including curved cuts and beveling of steel beams.

Laser Cutting

Laser Cutting

Replacing traditional CNC cutting and drilling methods, this machine quadruples production capacity by performing both operations simultaneously with exceptional speed and accuracy.

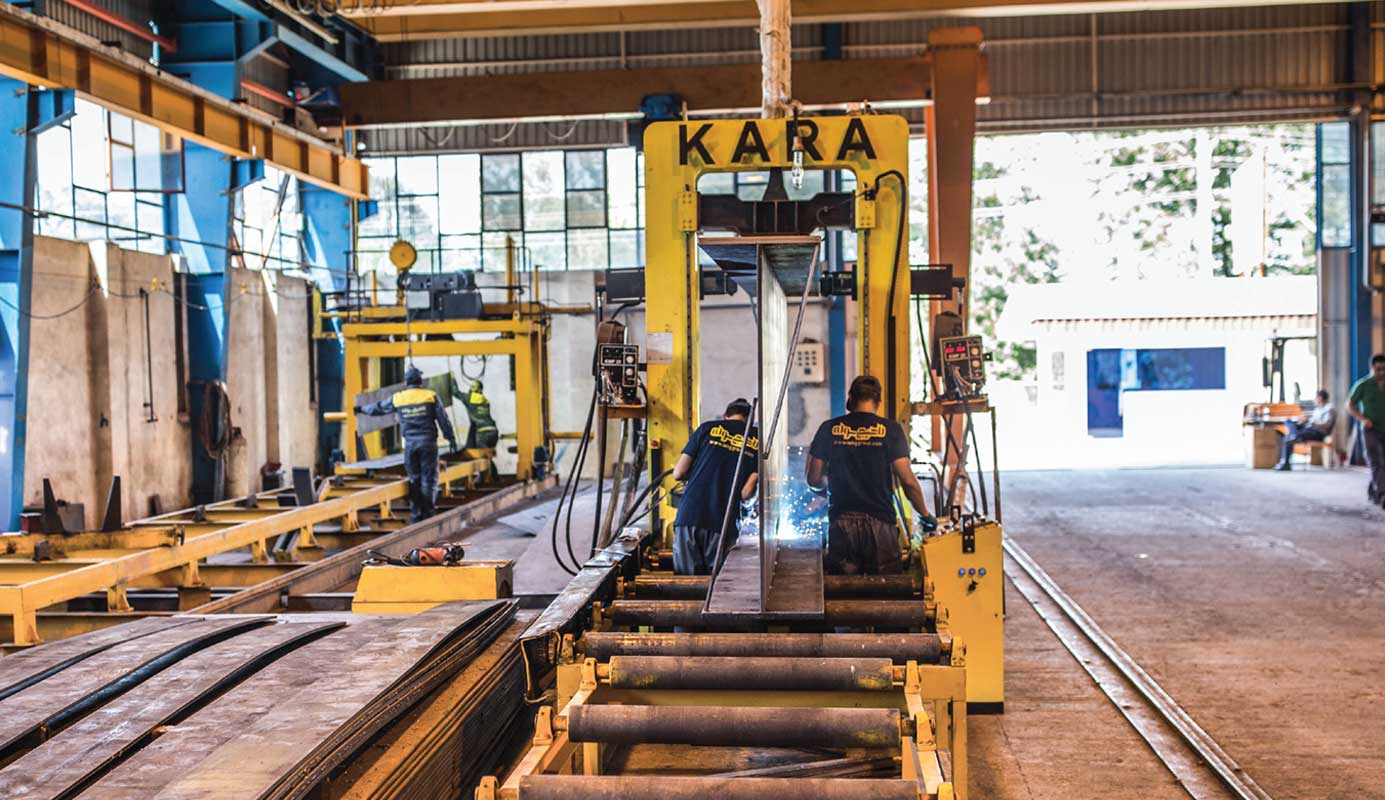

H‑Section Fabrication

H‑Section Fabrication

Lahij Souleh operates two fully automated H‑section fabrication machines with unlimited length capacity, producing all I‑ and H‑shaped beams to high technical standards, quickly and efficiently.

Shot Blasting

Shot Blasting

This equipment features a moving rail or a series of rotating cylinders that guide the workpiece into the shot blasting chamber for thorough surface treatment.

Rewinding Machine

Rewinding

Machine

The Lahij Souleh Factory is equipped with a high‑precision steel roll‑unwinding machine, capable of processing and flattening steel coils up to 20 millimeters in thickness. This advanced roll line can efficiently unroll heavy steel coils and convert them into perfectly flat sheets with exceptional dimensional accuracy, smooth surface finish, and uniform thickness. The presence of this machine, along with other modern fabrication equipment installed at Lahij Souleh’s production complex, enables the company to maintain full control over its raw‑material preparation and feedstock quality. By integrating automated coil handling, precision leveling, and cutting systems, Lahij Souleh achieves significant improvements in fabrication speed, production efficiency, and structural consistency. Such in‑house capabilities allow Lahij Souleh Construction Company to supply high‑quality flat steel plates tailored for various structural applications — including industrial halls, high‑rise buildings, bridges, and specialized medical facilities. The facility’s advanced material‑processing units exemplify Lahij Souleh’s commitment to technological innovation, engineering precision, and sustainable manufacturing within Iran’s construction industry.

Guillotine Machine

Guillotine

Machine

Cold Cutting and Guillotine Shearing Division Lahij Souleh Construction Company Within its Steel Fabrication and Equipment Division, Lahij Souleh Construction Company operates a highly specialized Cold Cutting Section, designed to meet the material‑preparation requirements of diverse structural projects. According to the specifications and scale of each project, this division utilizes an array of industrial‑grade guillotine shearing machines with cutting lengths of 6 meters, 3 meters, 2 meters, and 1 meter, enabling precise and efficient processing of steel sheets and plates. Each guillotine unit is equipped with high‑capacity hydraulic systems, digital alignment controllers, and precision blades designed for clean, deformation‑free cuts, ensuring that the resulting components maintain exact engineering tolerances. The availability of machines in multiple working lengths provides full flexibility for projects ranging from large‑span industrial halls and heavy steel frameworks to architectural and residential steel structures requiring fine detailing. Lahij Souleh’s cold‑cutting operations are fully integrated with its quality control and fabrication workflows, allowing the company to execute cutting, shaping, and assembly steps under strict safety and dimensional accuracy protocols. This technological setup guarantees consistency in production and optimizes material utilization, significantly enhancing construction efficiency and structural reliability across all project categories. By operating its own advanced cutting and shearing facilities, Lahij Souleh Sabz demonstrates a solid commitment to precision manufacturing, engineering excellence, and modernization of Iran’s steel construction industry, serving clients with the highest international standards in fabrication quality.

Laser Machine

Laser

Machine

The Industrial Laser Cutting Machine at Lahij Souleh Construction Company represents one of the most advanced technologies available in the field of metal cutting and precision fabrication. Utilizing a CNC fiber‑optic laser system, this equipment belongs to the newest generation of high‑performance industrial machinery and demonstrates the company’s commitment to innovation and production efficiency. Through the generation and controlled transmission of a high‑power laser beam via fiber‑optic channels, the system can cut a wide range of metallic materials — including carbon steel, stainless steel, aluminum, copper, and specialized alloys — with micrometer‑level precision. In the fiber‑laser cutting process, the laser beam is produced in the source unit and guided to the cutting head through a fiber‑optic cable. Specialized focusing lenses concentrate the beam to an extremely fine point on the workpiece surface, creating an intense localized temperature that instantly melts or vaporizes the metal. Then, a pressurized assist gas (such as oxygen or nitrogen) removes the molten material from the cutting kerf, forming smooth, burr‑free edges that require no secondary finishing. The advantages of this technology include exceptionally high cutting speed, the ability to reproduce complex geometric shapes, outstanding repeat accuracy, and significantly reduced energy consumption compared to traditional CO₂ laser systems. The CNC control interface allows operators to precisely program shapes, nesting layouts, and cut sequences, ensuring optimal material utilization, minimized waste, and improved production throughput.

PLASMA Machine

PLASMA

Machine

The Industrial Plasma Cutting Machine at Lahij Souleh Construction Company ranks among the most advanced and efficient technologies for cutting electrically conductive metals in modern fabrication. Operating on the principle of high‑pressure cathode and electric‑arc plasma technology, this system exemplifies cutting‑edge performance in precision steel processing. The plasma cutting process begins with the creation of an electric arc between the electrode and the workpiece. A strong electric current passes through a stream of compressed gas—typically air, oxygen, or nitrogen—raising its temperature to several thousands of degrees Celsius. This intense energy ionizes the gas, transforming it into a plasma state, which becomes capable of melting and separating metal instantly upon contact. The super‑heated plasma jet rapidly melts the targeted area of the metal surface, while the pressure of the gas forcibly ejects the molten material, delivering clean, accurate cuts with minimal heat‑affected zones. The result is a dramatic increase in cutting speed, exceptional edge quality, and a significant reduction in post‑processing or edge finishing requirements. Among the key attributes of Lahij Souleh’s plasma cutting system are its ability to cut sheets and components of various thicknesses, its compatibility with multiple metals including carbon steel, stainless steel, aluminum, and copper, and its precision in forming complex or intricate geometries.

CNC Cutting Machine-oxy-fuel

CNC

Cutting Machine

-oxy-fuel

To enhance the overall quality level of its products and meet the growing demand for modern metal‑cutting technology, Lahij Souleh Construction Company has equipped its manufacturing plant with an advanced CNC cutting system. This investment marks a major step toward precision fabrication and optimal geometry control in structural steel components. The CNC cutting equipment is designed to perform highly accurate cuts on steel plates and profiles of various sizes and thicknesses, shaping them into complex and customized contours with exceptional dimensional precision. It operates under full computer numerical control, allowing automated execution of programmed cutting paths and guaranteeing consistent quality across mass‑production batches. A notable engineering application of the system includes arc or curved cutting operations on the flanges of steel beams, particularly at locations where plastic hinge formation is expected under flexural loading, providing controlled geometry for structural integrity and ductility optimization. The CNC technology also supports angle‑cutting and bevel‑cutting processes, executing shapes of virtually any complexity. Its ability to maintain precise repeatability and tight tolerances makes it indispensable in fabricating bolted and welded joints, architectural steel components, and pre‑engineered assemblies.

CNC Drill

The utilization of the CNC drilling machine in Lahij Souleh Construction Company has provided the capability to perform precision drilling operations on steel plates according to customer specifications, varying patterns, and diverse dimensional requirements. Through its advanced programmable control, the CNC system enables automated creation of holes and cut‑outs across plates with absolute accuracy and repeatability. Once programmed, the machine can reproduce each component multiple times with consistent quality—eliminating manual error while ensuring high processing speed and production efficiency. This technology plays a vital role in modern steel fabrication, particularly in producing connection plates, beam joints, column end‑plates, and bolted assemblies, where dimensional precision and alignment are critical to structural performance.

CNC Drill

H section Welding Machine

H section

Welding Machine

Lahij Souleh Construction Company, equipped with two fully automatic H‑Beam production lines, is capable of manufacturing all I‑ and H‑shaped structural members with unlimited length capacity, delivering products of superior quality and high production speed across all engineering dimensions. These advanced fabrication systems perform precise assembly, automatic welding, straightening, and flange alignment for various steel profiles, ensuring optimum dimensional accuracy, uniform weld penetration, and full compliance with industrial fabrication standards. Utilization of such automated H‑Beam lines allows the company to meet diverse project requirements – from industrial halls and multi‑story structures to bridges and heavy steel frameworks – while maintaining exceptional efficiency, structural integrity, and production consistency. This technology reflects Lahij Souleh Sabz’s continuing commitment to precision engineering, large‑scale automated production, and excellence in high‑performance steel‑structure manufacturing, reinforcing its position among the leading structural engineering and fabrication specialists in Iran’s industrial sector.

BOX Section

Welding Machine

Through the installation and operation of its advanced Box‑Section Fabrication System, Lahij Souleh Construction Company has successfully resolved one of the major challenges in the manufacturing of box‑shaped steel sections—namely the issues of distortion, curvature, and torsional deformation that traditionally occurred during assembly and welding. This specialized equipment ensures precise alignment and full dimensional stability throughout the fabrication process, eliminating residual warping and delivering perfectly straight and geometrically accurate profiles. The integration of automated control and synchronized welding technology has brought about a significant improvement in production quality and fabrication speed, establishing a new standard within the company’s manufacturing workflow.

BOX Section Welding Machine

Positioner &

Transfer Machine

Within its assembly and welding lines, Lahij Souleh Construction Company utilizes advanced automatic and hydraulic positioner and transfer systems to optimize fabrication accuracy and workflow efficiency. These systems allow for precision rotation and controlled movement of heavy structural components during assembly, eliminating impact or vibration on parts while ensuring full stability throughout handling operations. This feature not only protects large and complex members from mechanical stress but also contributes to maintaining dimensional alignment and surface integrity during fabrication. A key advantage of these automated positioning systems lies in their ability to set exact angular orientations for each component during longitudinal and corner welding operations. By achieving ideal positioning, weld seams are formed with uniform leg dimensions and balanced penetration, resulting in superior weld quality, higher strength, and improved structural reliability.

Positioner & Transfer Machine

In this advanced fabrication method, box‑type column sections and box structural members, whose connection zones must comply with Section 10 of the Iranian National Building Regulations requiring the use of continuity plates and internal stiffeners, are welded through a modern, professional process that ensures extremely high precision and welding quality. In traditional fabrication techniques, it was common practice to cut open the plate at the joint area and create a “lozenge‑shaped opening” on the fourth face of the column to allow groove welding access. This approach concentrated welding stress on a single face, often causing undesirable longitudinal tension and distortion of the column. To avoid such deformation, many manufacturers simply omitted welding of the fourth face altogether, thereby compromising the structural continuity and integrity of the connection.

Electro Slag

Welding

Electro Slag Welding

Submerged

Welding Machine

Lahij Souleh Construction Company is equipped with an advanced and comprehensive Submerged Arc Welding (SAW) production line, comprising four gantry‑type SAW machines, six SAW truck units, and three SAW boom‑and‑column systems. These units collectively perform all full‑penetration welds required for the flange and web splicing sections of main structural components. The process is executed under fully automatic control, ensuring precise arc stability, uniform heat distribution, and high welding penetration quality across every joint. With this configuration, the company achieves a high‑speed, consistent, and defect‑free welding output, significantly enhancing both the strength and quality of structural assemblies. The implementation of this multi‑station SAW line reflects Lahij Souleh Sabz’s commitment to adopting state‑of‑the‑art fabrication technology, optimizing production efficiency, and upholding international welding standards throughout its steel‑structure manufacturing process.

Submerged Welding Machine

CO2 Welding

CO2 Welding

In previous welding practices, the connections of structural members were predominantly executed through manual shielded‑metal arc welding (SMAW) using thick electrodes (typically 4 – 5 mm). Due to electrode thickness and the presence of slag formation during arc welding, various defects frequently appeared along the weld bead, including insufficient penetration, lack of fusion at joint edges, and slag entrapment between welding passes. To completely eliminate these issues, Lahij Souleh Construction Company employs the CO₂ gas‑shielded welding method using 1.2 mm‑diameter wire electrodes for seam and groove joints. This process is operated under higher amperage, producing a stable molten weld pool while the protective CO₂ gas shield prevents slag accumulation between successive passes. The CO₂ welding system operates in a semi‑automatic mode, delivering exceptionally high weld quality, superior penetration, and improved surface finish across all structural components. This modern technique ensures greater mechanical integrity and consistency in Lahij Souleh Sabz’s steel‑structure fabrication process.

Shot blasting machine

Shot blasting Machine

This system consists of a motorized rail conveyor or a series of rotating cylindrical rollers that guide the workpiece smoothly into the shot‑blasting chamber. Both the inlet and outlet of the chamber are sealed by hanging elastic curtain strips, designed to prevent the escape of abrasive steel shots during the blasting process. This type of machine is specifically utilized in large‑scale industrial manufacturing facilities, offering superior operational power, throughput capacity, and surface‑finish quality compared with traditional sand‑blasting methods. Through this automated system, Lahij Souleh Sabz ensures uniform surface preparation, high precision, and optimal adhesion conditions for subsequent coating and welding operations—reflecting its commitment to advanced fabrication technology and quality excellence in the steel‑structure industry.

Sandblast & Painting

Sandblast & Painting

Lahij Souleh Construction Company operates a dedicated shot‑blasting and industrial painting hall, each spanning 300 square meters. Equipped with fully modernized surface preparation and airless coating systems, these facilities have enabled the company to elevate the finishing quality of its products to the highest standards of workmanship, meeting the technical requirements of SA3 surface treatment as defined in Section 10 of the Iranian National Building Regulations. Within Lahij Souleh’s automatic shot‑blasting section, fabricated members are conveyed along a motorized rail system, where simultaneous rust and scale removal across all surfaces is achieved through multi‑directional high‑velocity steel‑shot impact. This installation represents one of the most advanced corrosion‑removal technologies currently available worldwide. Following completion of the welding stage and dimensional and weld‑quality approval by the Quality Control Department, the fabricated component is transferred to the painting section. There, through precision solvent cleaning and deslagging equipment, all residual welding slag and impurities are removed, and the surface is polished to full smoothness prior to coating. The airless paint application system then performs uniform spray coating, after which the film‑thickness gauge measures paint layer thickness on each workpiece. Upon satisfactory verification, the coated components are transferred to the storage and dispatch area. This integrated production workflow allows Lahij Souleh Sabz to ensure consistent SA3‑grade surface quality, maximum corrosion resistance, and exceptional aesthetic and structural durability throughout all its industrial steel‑structure projects.

Logistic & Installation

Logistic &

Installation

For the execution of large‑scale construction and infrastructure projects, the presence of a fully integrated management system from fabrication through installation is an essential and inseparable part of all operational decision‑making processes. At Lahij Souleh Construction Company, comprehensive evaluation of executional constraints and installation challenges is conducted from the earliest stages of each project. Fabrication sequences are planned so that component delivery, loading, and transportation occur precisely in accordance with practical and executable installation schedules. From the onset, the crane positioning and lifting capacity at the jobsite are carefully assessed, and the manufacturing order is organized to correspond exactly with the lifting and assembly requirements during installation. The prioritization and dispatch order of structural members are therefore coordinated in full alignment with the installation plan—supported by Lahij Souleh’s advanced logistical systems and the technical expertise of its fabrication and erection teams. Lahij Souleh Sabz possesses a highly skilled and experienced installation division, equipped with a full range of lifting and transportation assets, including cranes of 50 tons, 20 tons, 10 tons, and 5 tons, together with tractor‑trailers and heavy hauling units, enabling efficient, timely, and cost‑effective project completion through the final stage of erection. Through this integrated management and execution system, Lahij Souleh Construction Company ensures precise scheduling, structural alignment accuracy, and the highest degree of efficiency in the fabrication‑to‑installation workflow for its steel‑structure projects.

Lahij Souleh 20‑ton and 50‑ton cranes in project operation